Table Of Content

Use Generative Design in Fusion to create multiple designs that meet your geometric, performance, and manufacturing requirements. You can then explore the designs to select the optimal one for manufacture. Ultimately, AI optimizes the manufacturing process from start to finish. With the integration of AI in robotics and automation, manufacturing plants are becoming more efficient and less prone to errors.

University College London Fusion 360 - Autodesk Redshift

University College London Fusion 360.

Posted: Fri, 27 Oct 2023 10:42:04 GMT [source]

Explore limitless possibilities with generative design

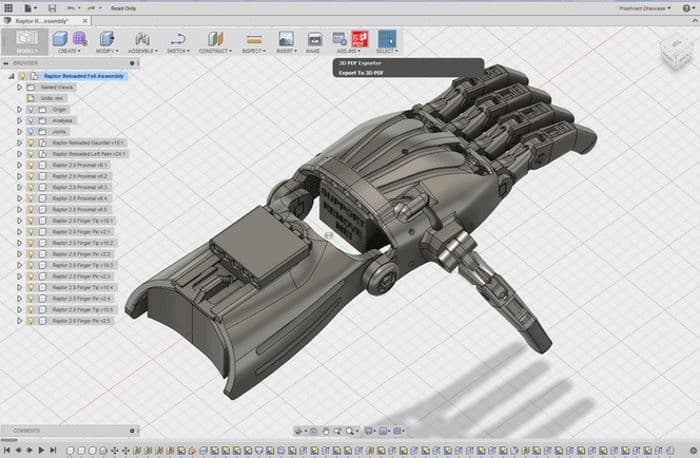

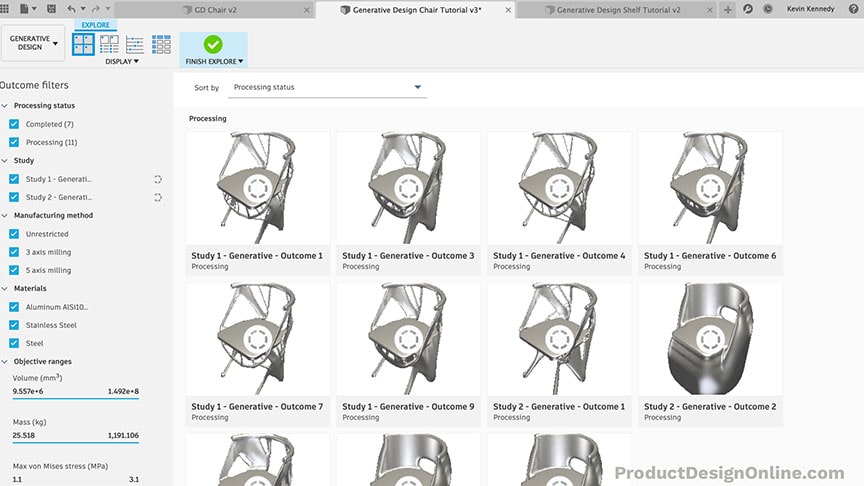

Generative design in Fusion 360 has some interesting options and these are expanding with each update. The most open option is to have the system work in an unrestricted manner. This means that it will build to optimise, without thinking about manufacturing method or processing. Thanks to the continuous work on design divergence, new Experimental Solvers offer up to four additional outcomes, plus the default ones, for every study setup.

Study definition

AI integration promotes proactive supply chain management, maintaining manufacturing processes even in unforeseen circumstances. Yes, the generative design technology does carry out a cursory simulation using your load cases, but this won’t be enough to validate whether these hyper-optimised forms can withstand real-world loading conditions. At this point in our workflow, we now have a shortlist of concepts from the generative design process that have both completed and converged. Each computation is iterative in nature (typically resolving in around 25 iterations).

The role of AI in manufacturing

This can be created either with or without an intact construction history and can then be taken through further workflows and validation, and eventually, perhaps, into production. Combined with the filters and grouping/colouring options, you can very quickly gain an understanding of how your experiments are progressing or have completed and where they lie on the performance front. With these, you can just about define the parameters of your machine tool capability.

Model Setup

Furthermore, AI is also making significant impacts within design and development areas. AI-powered tools can simulate and test various design scenarios in a fraction of the time it would take humans to do manually. An example might be using AI to simulate the stress and strain on various materials, helping designers to select the most durable choices for their products. By identifying potential issues early in the development cycle, AI helps to accelerate the design process and improve final product quality. A primary benefit of AI is its ability to analyze large datasets quickly and accurately.

We’re making AI-powered design accessible with an updated generative design price structure. Comparing these properties, we can see that the Factor of Safety for both is the same. However, maximum global displacement was reduced from 0.28 mm to 0.1 mm as it was constrained. Generative design is a form of artificial intelligence that leverages the power of the cloud and machine learning while accelerating the entire design-to-make process.

Prior to joining Autodesk, he worked as a CAE engineer for several companies in the automotive industry. As the Experimental Solvers feature is still being developed and improved, it is available as a preview feature. This means that to use it, you will need to enable it in the Preferences dialog box of Fusion 360. To do this, first open the Preferences window by choosing the Preferences option (4) inside the menu (3) in the upper right corner of the Fusion 360 window.

Autodesk Fusion 360 Basics: Library Features, Tools, and More - Autodesk Redshift

Autodesk Fusion 360 Basics: Library Features, Tools, and More.

Posted: Mon, 03 Jul 2023 07:00:00 GMT [source]

In the context of manufacturing, this capability is crucial for identifying trends, predicting outcomes, and making data-driven decisions. AI plays an important role in making manufacturing processes streamlined with its ability to catch errors that are often overlooked by humans. For example, computer vision AI systems can detect minute defects in materials or inconsistencies in production processes. AI’s ability to enhance these processes results in higher quality control, sustainability, and process optimization across the manufacturing line. Generative design has been enabling companies to overcome some of their hardest engineering challenges. It helps improve the performance of your product by light-weighting or improving structural integrity, while giving you the freedom to explore more design and manufacturing alternatives some of which go beyond human imagination.

Written by Autodesk University

He also completed postgraduate studies in software development methodologies. He joined Autodesk in 2016, and is currently working as a senior software engineer. He's been involved in generative design from the beginning of this project and is based in Krakow, Poland. Krystian Motawa graduated with a master’s degree in Structural Engineering. He’s been involved in generative design from the beginning of this project and is based in Krakow, Poland.

On opening it up, you’ll be presented with a grid-like window that shows each study underway, with a bunch of filters to the left-hand side. Each of these shows you the current state of a study in terms of geometry, and you can quickly arrange them by material, maximum stress, volume, completion stage and more. It’s at this early stage where we see one of the main points of difference between Autodesk’s approach to these tools and that used in other topology optimisation based systems to provide similar results. Get a free 30-day trial to explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight and improving performance. He graduated with a master's degree in Mechanical Engineering, specializing in Finite Element Method (FEM) simulations.

Starting today, we’re making generative design subscriptions accessible at a game-changing price point of $200 USD per month. Generative design in Autodesk Fusion 360 made its initial commercial debut in October of 2018. Since then, we’ve been learning a lot about how we can make it easier for you to try what we believe will be beneficially transformative to the way you design and engineer your products.

Generative Design is a multi-objective design exploration tool that helps you discover new ways to design parts with geometric, manufacturability, and performance constraints. After you specify initial inputs, it automatically provides you with multiple editable design solutions using a single cloud solve. Generative Design enables you to design beyond the human imagination and develop manufacturing-ready solutions that you might not otherwise consider. The manufacturing sector is no exception to the artificial intelligence (AI) technology revolutionizing most fields today. AI, beyond being a futuristic concept, is a practical tool that enhances manufacturing quality and efficiency. Product development professionals must understand AI’s industry impact and its role in transforming product design, development, and market launch.

We are a team of researchers at Carnegie Mellon University's Human-Computer Interaction Institute and Autodesk Research. Our group develops novel interfaces to help designers learn to better collaborate and co-create with AI systems on complex 3D CAD design tasks. Through our work, we aim to gather insights for developing future interfaces for generative AI design software. Only posts directly related to Fusion are welcome, unless you're comparing features with other similar products, or are looking for advice on which product to buy.

AI algorithms can control and optimize manufacturing equipment, supporting consistent and high-quality production outputs. With generative design in Fusion 360, by contrast, as you start computation, you can enter the Explore environment. This allows you to define a number of controls over geometry – specifically, overhang angle and minimum thickness of material allowable. There are also tools that help to save time; a good example is the fastener obstacle tool.

The above steps will enable the Experimental Solvers Tech Preview for your account. Now to explore alternative outcomes for a specific study, one more step is needed. After creating a new study, open its Study Settings (7,8) and select the Alternative Outcomes option (9). To limit global displacements in the considered model, we set the allowable maximum value 0.1 mm in all three orthogonal directions.

For this study, we are currently recruiting people with mechanical design experience and familiarity with at least one major CAD tool (Autodesk Inventor/Fusion, Solidworks, OnShape, etc.). This area of learning content consists of a series of tutorials that provide you with detailed, step-by-step instructions for a variety of different tasks, and are a great way to get started with the Generative Design in Fusion. This is where, in Fusion 360, you incur more cost, because to export concepts is going to cost you 100 cloud credits.

No comments:

Post a Comment